Denture Base properties

The plastic base from which supports the artificial teeth is formed using the die and counterdie method using brass mould templates. Acrylic resins in nature can be slightly weaker if allowed to rock in the mouth on bony anatomical structures. Since the failure of acrylic comes from transverse tensile stresses especially were impact is present then the introduction of carbon fibres or serrated stainless steel bars together with Hi Impact Diamond D have proved to be a Crack Stopper in the First Degree. Acrylic being strong to resist strain in compressive mode as in chewing and biting is however weaker when continual bending is imparted on the material. It is therefore imperative that your denture is regularily checked to ensure a 'rock free' environment exists for its continual success.

The Clinical Dental Technicians is the new professionals devoted to denture quality innovation and with their advice to manufacturers then future develpment and patient satisfaction should be ensured.

And so above reveals many years of research from the top firm in dentistry. I always refer to Ivoclar as the Rolls Royce of the tooth Industry.

My business has been based on the quality of Ivoclar products from Schottlander Enigma, Natura. The Vivadent PE to Antaris DCL then Vivadent DCL and now the 'Phonares'.

A Class of their own.

Poly Methyl Meth Acrylate (PMMA) most commonly referred to in 1937 as trade name 'Perspex'.

Used extensivelly in the aero industry during WW11 as cockpit shields as an alternate to glass. it imparted a shatterproof property as well as being optically stabile. There being little distortionas as with glass.

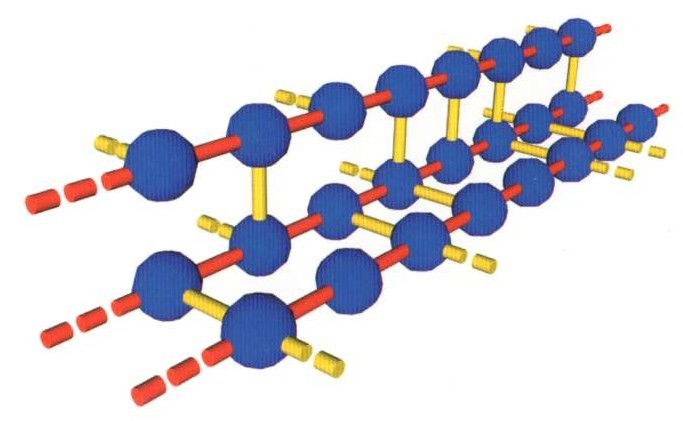

Denture bases and teeth are composed of modified acrylic containing a cross linking agent and impact resistent additive to impart greater flexural strain resistance without permanent distortion or failure. The diagram to the left is a Polymer structure of acylic with the cross linking agents illustrated in yellow. The blue balls are monomer with the red connectors being the polymer bonds between the monomer molecules.

The red cross linking imparts rigidity, colour stability, abrasion resistence and resistence to plaque attack. Without cross linking the acrylic wouldnt be suitable for long tem oral use.

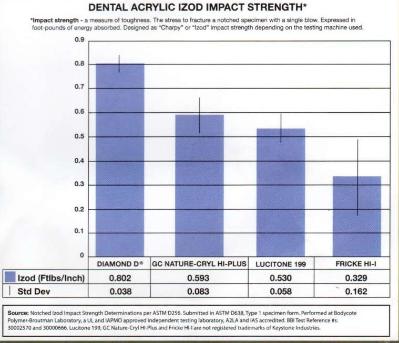

This produces a High Molecular weight resin PMMA with exceptional superior physical properties. One such acrylic that I use personally is Diamond D which is manufactured in the USA. As you can appreciate the strength is second to none and has surpassed Lucitone 190 which has been one the chosen private quality acylics for many a decade in the United Kingdom.

As an additional measure I incorporate a serrated stainless steel internal reinforcement which resists fractures from the most heaviest of bites. Since including this addition in my dentures twenty years ago I have encountered denture base failures.

The only failures I encounter is were excessive commercial beached based cleaning is undertaken with very hot water. Boiling water accelerates the bleach effect untill a porous white plastic results.

Tooth Acrylic Materials

In order to achieve optimum aesthetic properties from an artificial tooth surface the tooth has to be carefully designed using a spectrometer to deduce the angle, magnitude of reflectivity of light entering a natural tooth and digitally recording it.

From this information the scientists produce through careful lamination and grain size powder blending a laminated surfaces of quality such as Enigma and Ivoclar. The result is an optical 3D design, by such means and when viewed in natural daylight appear to replicate a 'Mother of Pearl'. Which is how a natural tooth develops.

Light entering the tooth on the facial aspect is reflected from the layers below the surface out of the tooth at different angle just like a natural tooth.

The Natural Hue is therefore transferred to the viewers eye. If the person has a reddish complexion then a correctly chosen tooth will naturally reflect a reddish tinge to the viewers eyes.

Aesthetic is not therefore just twisting teeth and cutting gaps between them but the use of expensive teeth such as Ivoclar-Vivadent PE and Enigma.

I will explain extensivelly on correct cleaning and caring for you dentures in the cleaning section on this website together with safe denture cleaning materials and ultrasonic equipment.

Tooth Material Development

Development in material has seen the cross linking mechanism being introduced in the 1960's.

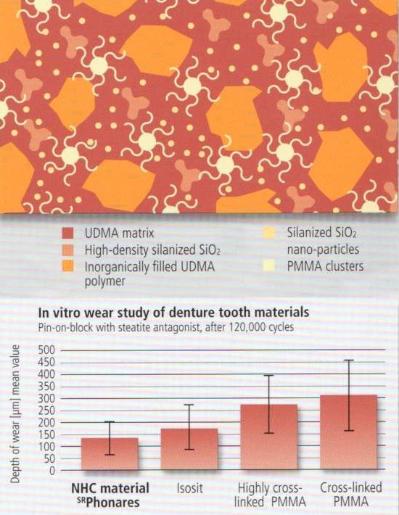

Now manufactures have introduced double cross linking improving still further and together with composite (isosit) introduction are producing tooth materials with exceptional surface toughness resistence to wear and acid alkali liquid attack. Manufacturers such as Ivoclar from Liechenstein have introduced Ivoclar Vivadent DCL (double crossed linked) and with composites have introduced their latest superior range that of 'Phonares'. These teeth have revolutionised to way we view natural teeth, their shape, shade, development and ageing reproduction. So that 21yr old teeth are not placed on an elderley persons denture. Below are included the constituents of the tooth material and the results of testing. You will observe the inclusion of the Nano particles and Silicone dioxide has drastically reduced the wear of these new phonares teeth.